Black oxide as your choice of barbell finish will offer distinct advantages and disadvantages.

Black oxide vs stainless steel barbell.

Given enough time water and oxygen any piece of steel will begin to rust and preventing and controlling.

Black oxide or blackening is a conversion coating for ferrous materials stainless steel copper and copper based alloys zinc powdered metals and silver solder.

A power bar is more likely to be finished with hardened chrome vs black oxide or black zinc.

This process will add a layer of chromium to your bar and will give it a shiny silver color.

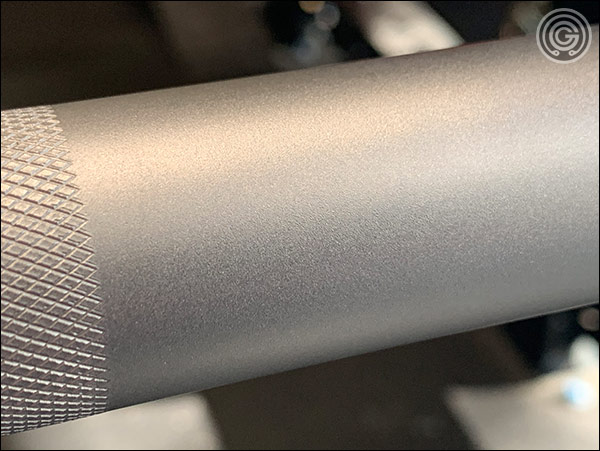

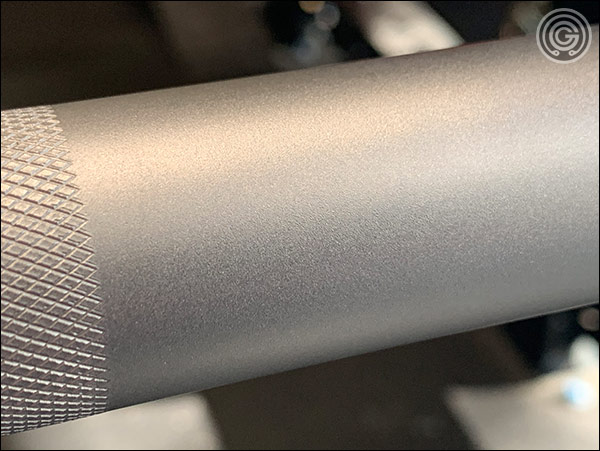

Black oxide is a very minimal finish that gives the bar a cool black look.

As you no doubt know when iron is exposed to both oxygen and water generally moisture in the air rust will form.

The shaft is black oxide which is a commonly used barbell finish.

Stainless steel is the holy grail of barbell.

Plating also knocks down the knurl so the stainless knurl feels so much better than the zinc bars.

It is used to add mild corrosion resistance for appearance and to minimize light reflection.

The absolute oxide bar has a recessed knurl.

Should you even consider purchasing one of the classic bars or is the new ss ohio a no brainer.

I am particularly talking about the new leatherman multi tools with a black oxide finish vs their normal stainless steel tools.

A surprising thing rogue found out was that the finish plating on a bar shaft impacted the shaft s durability.

For sleeves it needs to be chrome or stainless bright zinc a very distant 3rd.

Steel versus stainless steel.

A black oxide variant is offered for just a few bucks more at.

Not just in terms of surface scratches or rust but literally causing a bar.

Arguably one of the best features of black oxide will be the feel of the knurling.

The classic ohio bar has a base price of 282 and it is a zinc bar.

Of all the finishes it interferes with bar feel the least.

It is intentionally cut to a shallower depth than its outer.

I don t unfortunately know what kinda of stainless.

Steel is a combination of iron and carbon.

To achieve maximal corrosion resistance the black oxide must be impregnated with oil or wax.

Power lifters don t need to feel as connected to the bar as an oly lifter does.

That is a major difference between these two bars.

It does provide some corrosion protection but not much.

But other than that it should last a lot longer than zinc or black oxide coatings.

The stainless ohio is awesome.

I m wondering if a black oxide finish on stainless steel is more or less durable then simple stainless steel.

But let s talk about the center knurl.

When chloride is also present all you coastal dwellers the oxidation process is accelerated.

One of its advantages over other coatings is.

For shaft stainless preferred.

Stainless steel vs cerakote barbell.

The knurling rough part of the bar is going to provide you with a bare steel feel.

A weird note on steel durability.

The benefit of doing this is an increase in bar strength and excellent corrosion.

You will find yourself needing to maintenance this finish fairly often.

I would never consider black zinc or cerakote for sleeves.

So how do the classic ohio bars stack up to the new stainless steel ohio.